Lapho ucaphuna amaphrojekthi we-prototype, kuyadingeka ukukhetha izindlela ezifanele zokucubungula ngokuya ngesici sezingxenye ukuze uqedele amaphrojekthi we-prototype ngokushesha nangcono.Manje, igxile kakhulu ekucubunguleni i-prototype, ukucutshungulwa kwe-lathe, ukuphrinta kwe-3D, ukuqopha, ukubunjwa okusheshayo, njll. Namuhla sizokhuluma ngomehluko phakathi kokucubungula i-lathe nokuphrinta kwe-3D.

Okokuqala, ukuphrinta kwe-3D kuwubuchwepheshe obandisiwe, futhi ukucutshungulwa kwe-lathe kuwubuchwepheshe obuncishisiwe, ngakho bahluke kakhulu ezintweni zokwakha.

1. Umehluko ezintweni

Izinto zokuphrinta ezinezinhlangothi ezintathu ikakhulukazi zifaka i-resin ewuketshezi (i-SLA), impushana enayiloni (SLS), impushana yensimbi (SLM), i-gypsum powder (ukuphrinta ngombala ogcwele), impushana ye-sandstone (ukuphrinta ngombala ogcwele), ucingo (DFM), ishidi ( I-LOM), njll. I-resin engamanzi, impushana enayiloni nempushana yensimbi kuthatha ingxenye enkulu yezimboni zokunyathelisa ze-3D.

Izinto ezisetshenziswa ekucubunguleni i-lathe yiwo wonke amapuleti, ayizinto ezifana nepuleti.Ngokulinganisa ubude, ububanzi nobude bokugqoka izingxenye, amapuleti asikwa ukuze acutshungulwe.Isilinganiso sempahla yokucubungula i-lathe ukuphrinta kwe-3D.Ngamafuphi, i-hardware kanye namapuleti epulasitiki angacutshungulwa nge-lathe, futhi ukuminyana kwezingxenye ezibunjiwe kuphakeme kunaleyo yokuphrinta kwe-3D.

2. Umehluko ezingxenyeni ngenxa yesimiso sokwakha

Njengoba sishilo ekuqaleni, ukuphrinta kwe-3D kuwuhlobo lokukhiqiza okungeziwe.Umgomo wayo ukusika imodeli ibe ngamaphoyinti amaningi angu-N/N, bese uwanqwabelanisa ngongqimba/iphuzu nephuzu ngokulandelana, njengamabhulokhi wokwakha.Ngokufanayo.Ngakho-ke, ukuphrinta kwe-3D kungacubungula ngempumelelo futhi kukhiqize izingxenye ezinezakhiwo eziyinkimbinkimbi, njengezingxenye ezingenalutho, kuyilapho i-CNC kunzima ukubona ukucutshungulwa kwezingxenye ezingenalutho.

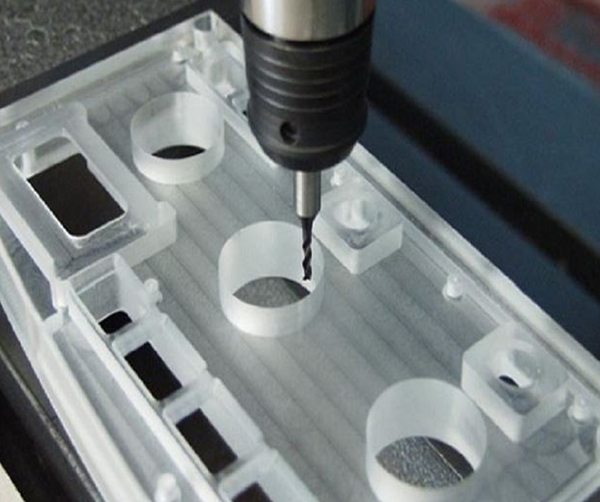

I-CNC iyindlela yokunciphisa ukucutshungulwa kwezinto.Ngokusebenza ngesivinini esiphezulu kwamathuluzi ahlukahlukene, izingxenye ezidingekayo zisikwa ngokwemimese ehleliwe.Ngakho-ke, i-lathe ingaba namakhona ayindilinga we-arc ethile kuphela, kodwa ayikwazi ukucubungula ngokuqondile ama-engeli angakwesokudla, angabonakala ngobuchwepheshe bokusika intambo/inhlansi.Ukucubungula i-lathe ye-engeli yesokudla yangaphandle akuyona inkinga.Ngakho-ke, izingxenye zangaphakathi ezinama-angle kwesokudla zingabhekwa njengokukhetha ukucutshungulwa nokukhiqizwa kokuphrinta kwe-3D.

Uma indawo engaphezulu yengxenye inkulu kakhulu, kunconywa ukuthi ukhethe ukuphrinta kwe-3D.Ukucutshungulwa kwe-lathe kudla isikhathi esiningi, futhi uma abaphathi bemishini yokuhlela neyokusebenza bengenalo ulwazi olwanele, abakwazi ukushiya amaphethini acacile ezingxenyeni.

3. Umehluko ohlelweni lokusebenza

Iningi le-3D printing slicing software kulula ukuyisebenzisa, ngisho nomuntu ongenzi lutho angasebenzisa isofthiwe yokusika ngobunono usuku noma ezimbili ngaphansi kokuqondisa kochwepheshe.Ngenxa yokuthi isofthiwe yokusika ilula kakhulu ukuyilungiselela, ukusekelwa kungenziwa ngokuzenzakalelayo, yingakho ukuphrinta kwe-3D kungafinyelela kubasebenzisi ngabanye.Isoftware yokuhlela ye-CNC iyinkimbinkimbi kakhulu futhi idinga ochwepheshe ukuthi bayisebenzise.

4. Umehluko ekucutshungulweni kwangemuva

Azikho izinketho eziningi zezingxenye zokuphrinta ezinezinhlangothi ezintathu ngemva kokucubungula.Ngokuvamile, ziyapholishwa, zifuthwe, zikhishwe, futhi zidayiwe.Ngaphezu kwalokhu okushiwo ngenhla, kukhona i-electroplated, isikrini sikasilika esiphrintiwe, esiphrintiwe, esifakwe i-anodized, esiqoshwe nge-laser, esifakwe isihlabathi, njll.Okungenhla umehluko phakathi kokucubungula i-lathe ye-CNC nokuphrinta kwe-3D.Ngenxa yokuthi uhlelo luyinkimbinkimbi kakhulu, ingxenye ingaba nezinhlelo eziningi zemishini ye-CNC, futhi ukuphrinta kwe-3D kuzoba nomgomo olinganiselwe ngenxa yokubekwa kwengxenye encane yezinto ezisetshenziswayo zesikhathi sokucubungula.

Isikhathi sokuthumela: May-12-2022