Iyini i-Metal Die Casting?

I-Die Casting ibhekisela ohlelweni lokukhiqiza izingxenye zensimbi ezakhiwe isikhunta.Le nqubo ivumela imikhiqizo ukuthi yenziwe ngesilinganiso sokukhiqiza ngobuningi ngekhwalithi ephezulu kanye nokuphindaphinda.Inqubo iqala ngokuphoqa insimbi encibilikisiwe ngaphansi kwengcindezi ephezulu ibe ukhonkolo ofile.I-die ingaba nembobo eyodwa noma eminingi (izimbobo ziyisikhunta esakha isimo sengxenye).Uma insimbi isiqinile (ngokushesha njengemizuzwana engu-20) bese kuvulwe i-fasi bese isibhamu (amasango, abagijimi kanye nezingxenye zonke ezixhunyiwe) ziyasuswa futhi inqubo iqala futhi.Ngemva kokusebenza kokudubula, isibhamu sivame ukucutshungulwa ngokuqhubekayo endaweni yokunquma lapho kukhishwa khona amasango, abagijimi kanye ne-flash.Khona-ke ingxenye ingacutshungulwa ngokuqhubekayo ngokudiliza kwe-vibratory, ukudubula ukuqhuma, ukukhanda imishini, ukudweba, njll.

Izinzuzo Ze-Die Casting

I-Aluminium die Casting iyinqubo evamile kakhulu yokukhiqiza izingxenye zokuphonsa ze-aluminium ezisetshenziswa ezimbonini ezihlukahlukene.Njengoba i-aluminium inokugeleza okuhle kakhulu kwempahla, ukumelana nokugqwala okukhulu kanye nokuzinza kwe-dimensional ephezulu enezingxenye eziyinkimbinkimbi ezibunjiwe.

Ingxenye ye-aluminium die casting ingamandla aphezulu emishini, kulula ukuyisakaza, futhi inezindleko eziphansi uma kuqhathaniswa nezinc noma izingxenye ze-magnesium die casting.

Izingxenye zokuphonsa ze-Aluminium zinezinto ezibonakalayo ezinhle ezimelana nezinga lokushisa eliphezulu, okwenza ukusakaza kwe-aluminium kusetshenziswe ezimotweni, ezindizeni, zezokwelapha, nakweminye imikhiqizo yezimboni.

Izinyathelo Ezinhlanu

Isinyathelo 1. Ukuncibilika Kwempahla

Njengoba i-aluminium inephuzu lokuncibilika eliphezulu kakhulu (660.37 °C) elingakwazi ukuncibilika ngaphakathi komshini wokulingisa ifa ngokuqondile.Yingakho sidinga ukuyincibilikisa ngaphambili ngesithando somlilo esifakwe kusoumshini wokuwasha.

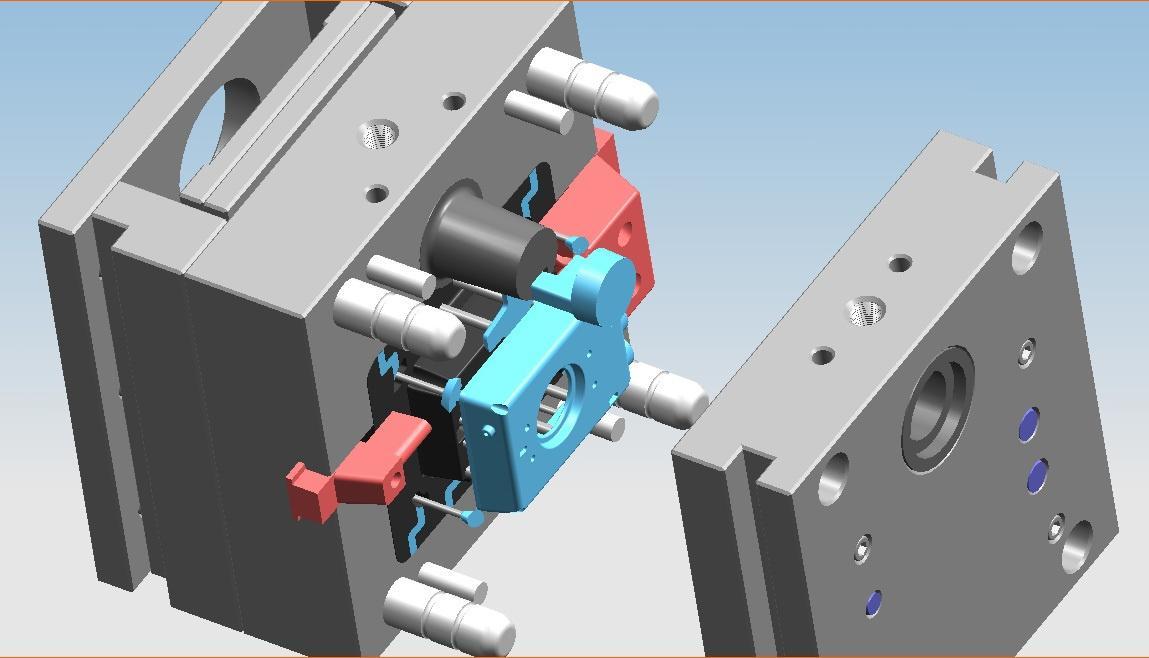

Isinyathelo sesi-2. Ukukhwezwa kwethuluzi lesikhunta kanye nokuhlanganisa

Icishe ifane nokubumba umjovo, inqubo yokufaka i-die cast nayo idinga ithuluzi lokubumba lenqubo yokuphonsa.Ngakho-ke, sidinga ukukhweza ithuluzi lesikhunta se-die casting endaweni ebandayo yokuphonsaumshini.

Isinyathelo 3. Umjovo noma Ukugcwalisa

Impahla encibilikisiwe idluliswa isuka esithandweni iye emshinini wokuphonsa nge-ladle enyakazayo.Kulesi sigaba, i-material izothululwa futhi iphoqelelwe emgodini wesikhunta sokufa laphoimpahla iyaphola futhi iqine ukuze kutholwe imikhiqizo efiselekayo yokufa.

Isinyathelo 4. Ukupholisa nokuqinisa

Ngemuva kokuthi ithuluzi lesikhunta se-die casting ligcwaliswe ngokuphelele ngezinto ezincibilikisiwe, kuthatha imizuzwana eyi-10 ~ 50 ukuthi liphole futhi liqiniswe (kuya ngengxenye yesakhiwo nosayizi).

Isinyathelo 5. Ukukhipha Ingxenye

Lapho isikhunta sivuleka, izingxenye eziphonsiwe zizokhishwa ngezikhonkwane ze-ejection ezivela kuthuluzi lesikhunta se-die casting.Khona-ke izingxenye ze-casted eluhlaza sezilungile.

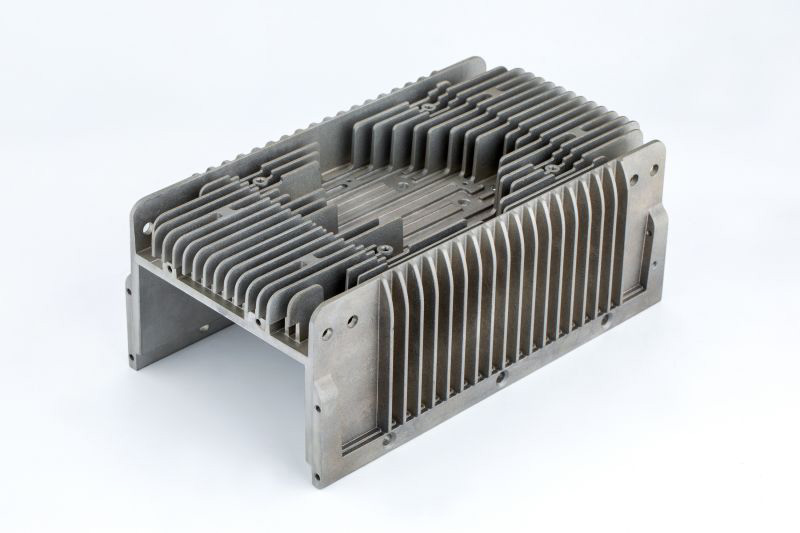

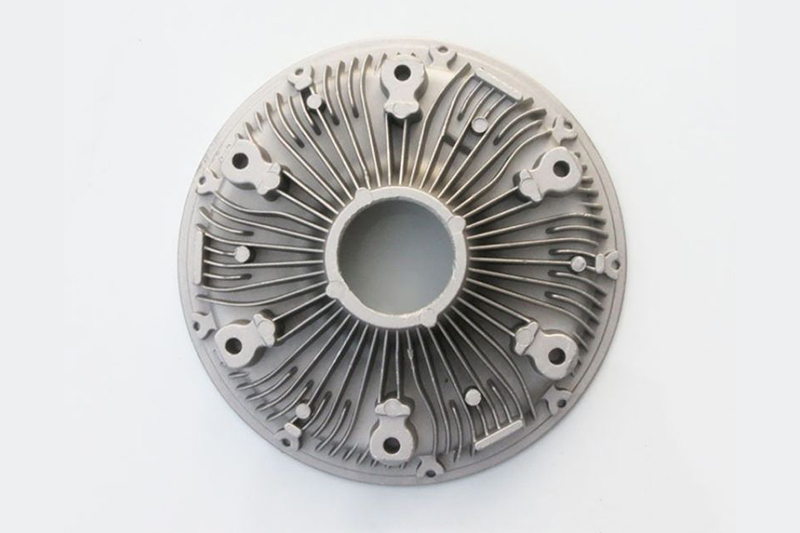

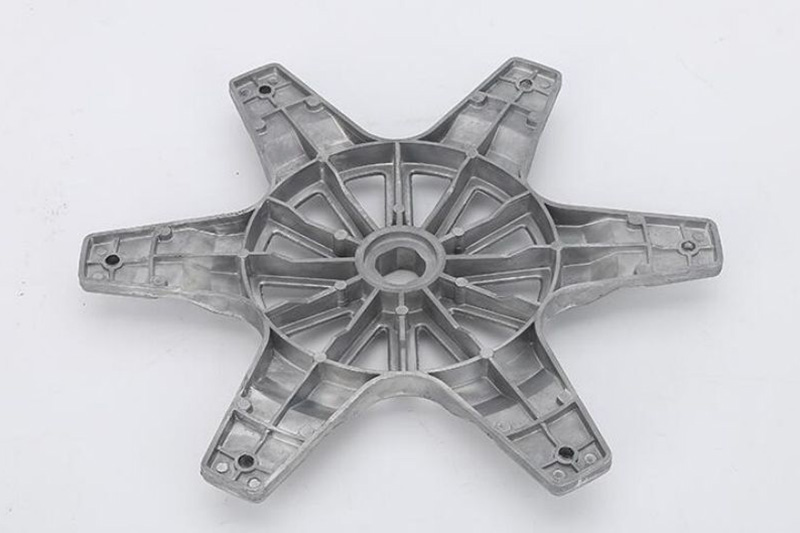

I-Die Casting Parts Showcase

Rapid Prototype Tooling Ingxenye

Izingxenye Zokusakaza Eziningi Zokukhiqiza

Ingxenye yokusakaza ye-Custom Die

I-Die Casting Part Ngaphandle Kokuqeda Ukwelashwa

Ingxenye ye-Prototype Tooling